Lifting high-speed disperser/dissolver, also called high-speed mixer. This machine is suitable for high-speed stirring, dissolution and dispersion of liquid and liquid-powder phase materials in paint, coatings, dyes, inks, pigments, cosmetics, resins, adhesives, emulsions, medicine, petroleum, and other fields.

The equipment used for pre-dispersion is mainly high-speed dispersion machine.Pre-dispersion can mix the pigment with part of the paint to become a semi-finished pigment paste.It is the first process of color paste production.Therefore,purpose of pre-dispersion is to:

①make the paint mix uniformly;

②make the pigment partly wet;

③preliminarily break up large pigment aggregates.

In summary,It is mainly for mixing, which plays a part of dispersing effect, and prepares for the next grinding process. The quality of the pre-dispersion effect directly affects the quality and efficiency of grinding and dispersion.

In addition to being used as dispersion equipment,the lift-type high-speed disperser can also be used as a production equipment.For example,the pigments used in the products are easily dispersible pigments,or the fineness of the products is not high.In this case,high-speed disperser/dissolver can be used directly and alone to produce paints,coating or other products.

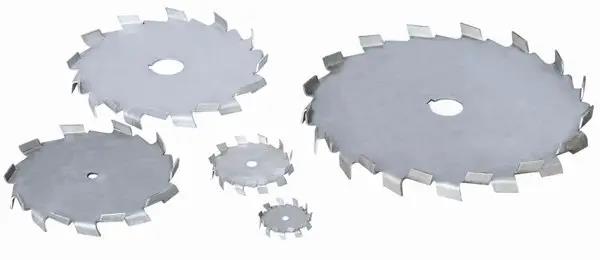

The zigzag-shaped circular dispersing disc of high-speed disperser rotates at high speed in the container to do the solid-liquid dispersion, wetting, de-aggregation and stabilization process.its working principle as below:

① Make the slurry flow in a rolling ring shape,generating a strong vortex,and the particles on the surface of the slurry will spiral down to the bottom of the vortex;

② A turbulent area is formed at the edge of the dispersion disc at 2.5-5mm,and the slurry and particles are subjected to strong shear and impact;

③ The upper and lower beam current are formed outside the area, and the slurry is fully circulated and turned;

④ Laminar flow is under the dispersing disc of the dispersing machine, and the slurry layers with different flow rates diffuse each other to play a dispersing effect.

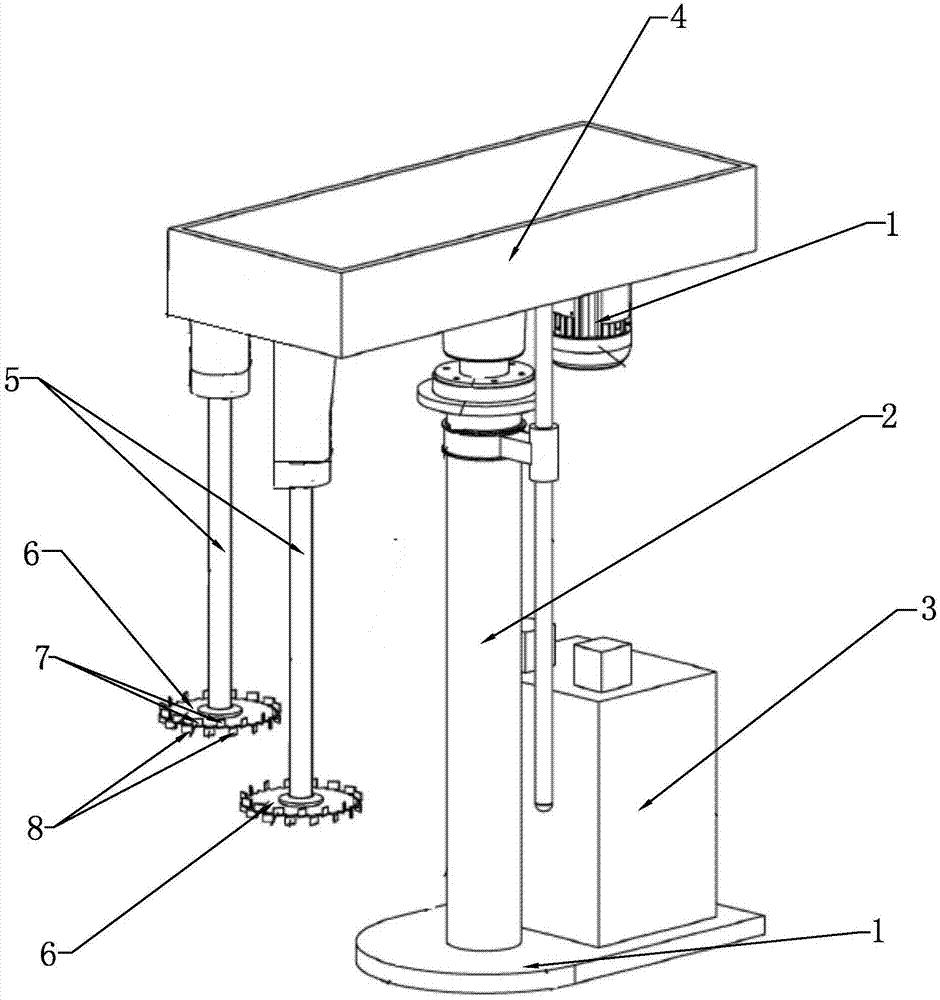

High-speed dispersion machine has multiple functions such as hydraulic lifting,with scraper/vacuum/lifting cover,360-degree rotation. and It can be equipped with 2-4 containers at the same time.The 360-degree rotation function can better meet the multi-purpose of one machine.It can change from one tank to another in a short time for operation,which greatly improves working efficiency,but also reduce the intensity of manual labor.(see picture below)

Lifting type high speed dispersing machine can be divided into single shaft dispersing machine, double shaft dispersing machine according to the production requirement.The speed regulation of high speed disperser usually adopts stepless speed regulation (such as for water-based coatings),and explosion-proof frequency conversion speed regulation (such as for solvent-based coatings) and other forms. According to the way of lifting can be divided into hydraulic lifting, pneumatic lifting, manual lifting and so on.

The speed of high speed disperser normally is during 0-1500rpm for industrial level.Actually,it usually use 4 phase motor at 1500rpm when power lower than 75KW for industrial disperser.However,the original motor speed does not means final shaft speed. It can be adjusted and set by transmission ratio and frequency inverter. Besides,higher speed does not always mean better dispersing effect,because linear velocity is the key indicator.As we know,Linear velocity=perimeter*shaft speed.Therefore,it is not correct to think that higher speed must mean better dispersing effect.

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China