The process of paint&coating&ink production is to mix the solid particles of pigments and fillers into the liquid(solvents,resins or binders,additives)to form a uniform and fine suspension dispersion. (For inks,only means pigment ink,not dye ink.and some products have no fillers.)

The primary particles of pigments&fillers are very fine, and normally their particle size is about 0.01~2μm.However,the particles of raw materials are often bonded into aggregates (secondary particles) during processing and storage. Finally their particle size may increase to 100μm up. As mentioned above, it is necessary to de-aggregate in paint&coating&ink manufacturing and disperse them stably and evenly in the final products.

During the process, the selected grinding and dispersing equipment play a vital role on the dispersion result of the pigment, the pigment performance (tinting power, hiding power, etc.)and the resulting performance of the film. Therefore, there are mainly two crucial factors for improving the dispersion effect in the production:

1.Using high-efficiency and high-performance dispersion&grinding equipment.

2.Selecting high-quality raw materials and good formulation.

(This articles only try to clarify in the aspect of dispersion and grinding tech.With regards to formulation,it belongs to expertise of chemist.)

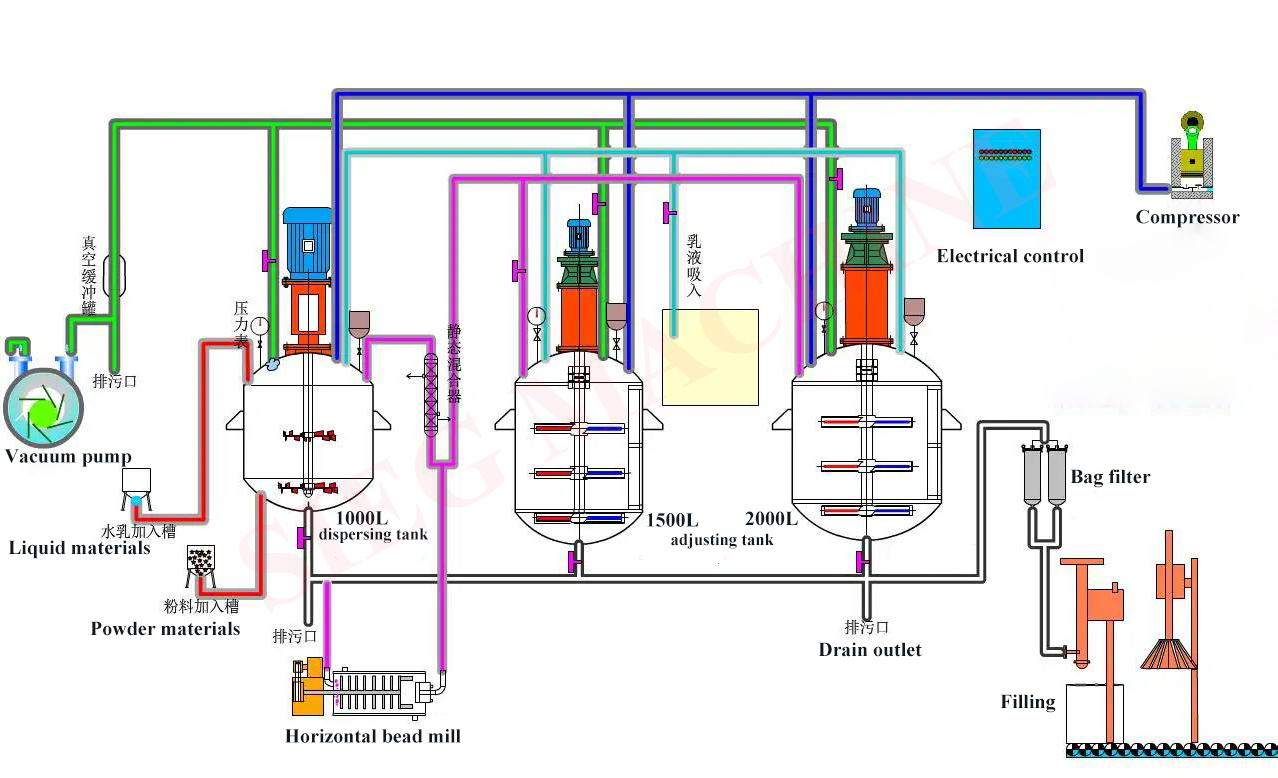

In summary,the following four steps are usually production flow:

1.Pre-dispersion or production: This process is mainly for mixing and has a certain dispersing effect,which is a preparatory process for fine grinding.it commonly use high speed disperser/dissovler.(It does not need do grinding for many paints and caatings which has no fineness requirement or it used expensive super-fine raw materials.In this way,it can get the final products without fine grinding.)

2.Grinding and dispersing equipment: such as vertical sand mills, horizontal sand mills,three-roller mills and basket mills

3.Adjusting.

4.Filter&packaging(filling).

Besides, there are some other mixers for high viscosity materials, such as butterfly mixer,dual shaft high speed disperser,compound agitators(high speed+low speed+scrapers),frame mixer,anchor mixer,planetary mixer,ribbon mixer. these machines most often combine together.At the same time,most of equipment can be customized based on actual production requirement,such as:

Floor type or top-mounted type(with reactor and platform),

Vacuum( for avoiding pungent solvents and bubbles)

Scraper for high viscosity materials,

Heating (steam or electrical) or cooling by jacket( water circulation)

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China