Product name: kneader,sigma mixer

Model:KDM series

Function: kneading,stirring,mixing

Application:sealant, silicone rubber, hot melt adhesive,food glue base,gums,etc

SIEGMA-Fly your success!

Introduction:

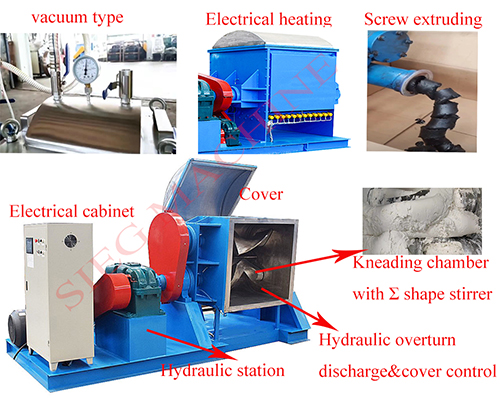

KMD series kneading machine(also called sigma mixer) is an ideal equipment for kneading, mixing,vulcanization and polymerization of high viscosity and elastoplastic materials.Kneader do kneading, stirring and shearing by a pair of matched and rotated sigma shape (Σ) stirrers. Besides,the rotation speed of the two stirrer is different to produce higher shear force and kneading effect. In this way, the semi-solid viscous material can get uniform mixing effect.

KMD seires kneading machine is mainly composed of five parts: kneading part, base, hydraulic system, transmission system and electric control system.

Kneading machine is widely used in processing high viscosity and semi-solid materials such as sealant, silicone rubber, hot melt adhesive, food glue base, pharmaceutical preparations, space sand, Plasticine, neutral acid glass glue, chewing gum, bubble gum, paper pulp, cellulose, battery, ink, pigment, dye, medicine, resin, plastic, rubber, cosmetics and other industries.

Main Features:

The stirrer and the inner wall of the cylinder ( contact parts with material) are made of SUS304 stainless steel or SUS316L stainless steel to ensure the purity of the products.

Kneader discharging mode: hydraulic overturn; screw extruding;bottom ball valve discharge.

The kneader installed two Σ shape stirrers, which can be set at different speeds according to different processes. The common speed is 20-40rpm.

Kneader can be designed into heated and non-heated type according to requirements. The heat exchange methods usually include electric heating, steam heating, circulating hot oil heating, circulating water cooling, etc.

Kneader can be made into common type, pressure type, vacuum type and high temperature type

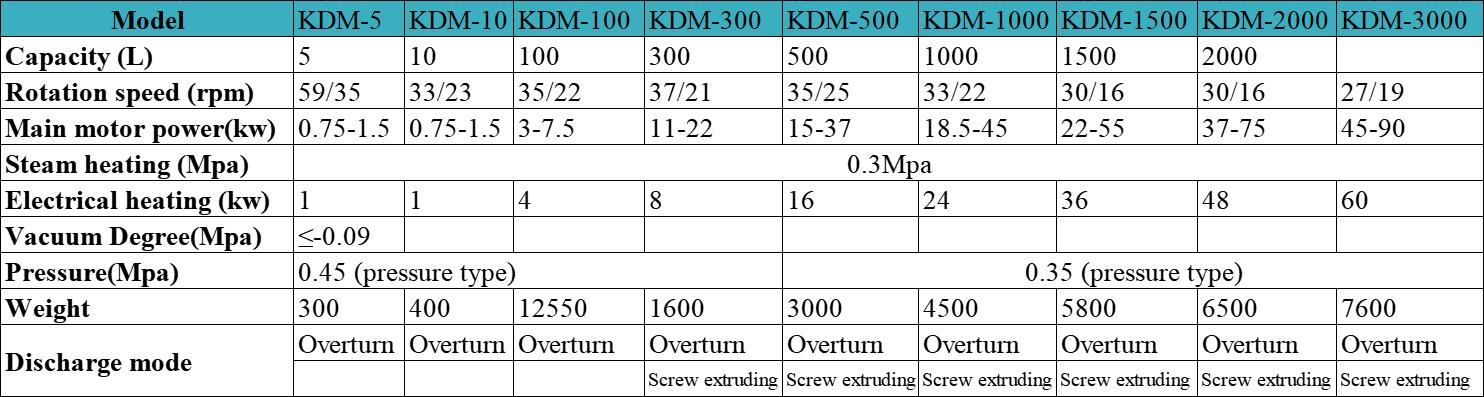

According to the volume of kneading chamber is divided into: 5-3000 liters

Kneader inner surface roughness: mirror polishing, fine polishing, rough polishing

Technical Specification:

Note:Considering materials property can affect result a lot, all data is just for reference. pls must contact our processing engineer for selecting proper specification.

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China