Product Name: High speed disperser/dissolver

Model:HSD Series

Function: mixing,dissolving,dispersing

Application:for making paint,ink,coating,etc

SIEGMA-Fly your success!

Introduction:

HSD series high speed disperser is suitable for mixing, dissolving and dispersing liquid with liquid and powder in liquid materials at high speed, so it is widely used in paint, coating,dye, ink, pigment, cosmetics, resin, adhesive, emulsion, medicine, food, petroleum and other industrial fields.

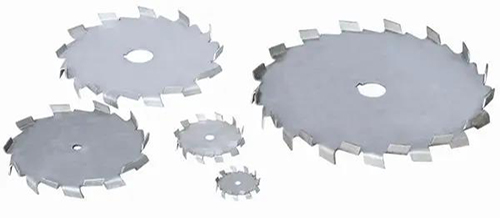

Broadly speaking,high speed dispersing machine is another type of mixer so that it is also called high speed mixer. High speed stirrer (such as the serrated disc) can form a strong turbulent flow around materials, which make a strong dispersion effect on the material. Therefore,high speed mixer is called high speed disperser.

High speed disperser is mainly divided into lifting floor-mounted type and top-mounted type on the reactor(with or without paltform). Furthermore,lifting type disperser can be divided into hydraulic lifting disperser, pneumatic lifting disperser, electric lifting disperser, manual lifting disperser according to the lifting mode. Besides,It can be divided into single shaft disperser or double shaft disperser according to shaft quantity.

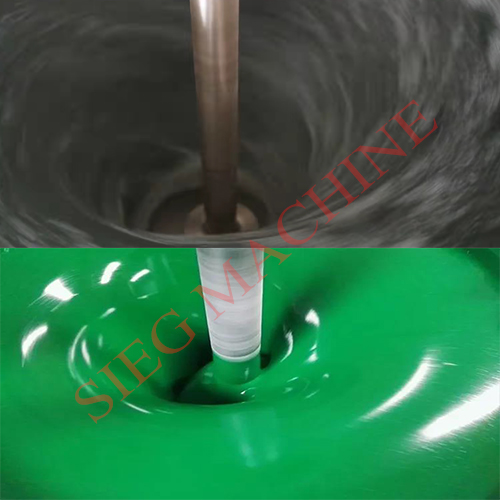

Working Principle:

The zigzag dispersing disc of high-speed disperser rotates in the container at high speed to finish the process of solid-liquid dispersion, wetting and deagglomeration.

No.1:The particles on the surface of the slurry descend to the bottom of the vortex in a spiral shape.

No.2:The turbulent zone is formed at the edge of the dispersion disc 2.5-5mm and the particles are subjected to strong shear and impact;

No.3:The upper and lower beams are formed outside the zone, and the slurry is fully circulated and turned.

No.4:The area under the dispersing disk is laminar flow, and the slurry layers with different flow rates diffuse with each other to achieve the dispersing effect.

Main Features:

Variable speed by frequency converter

Explosion-proof grade can reach to zone 1(ExdIIBT4)

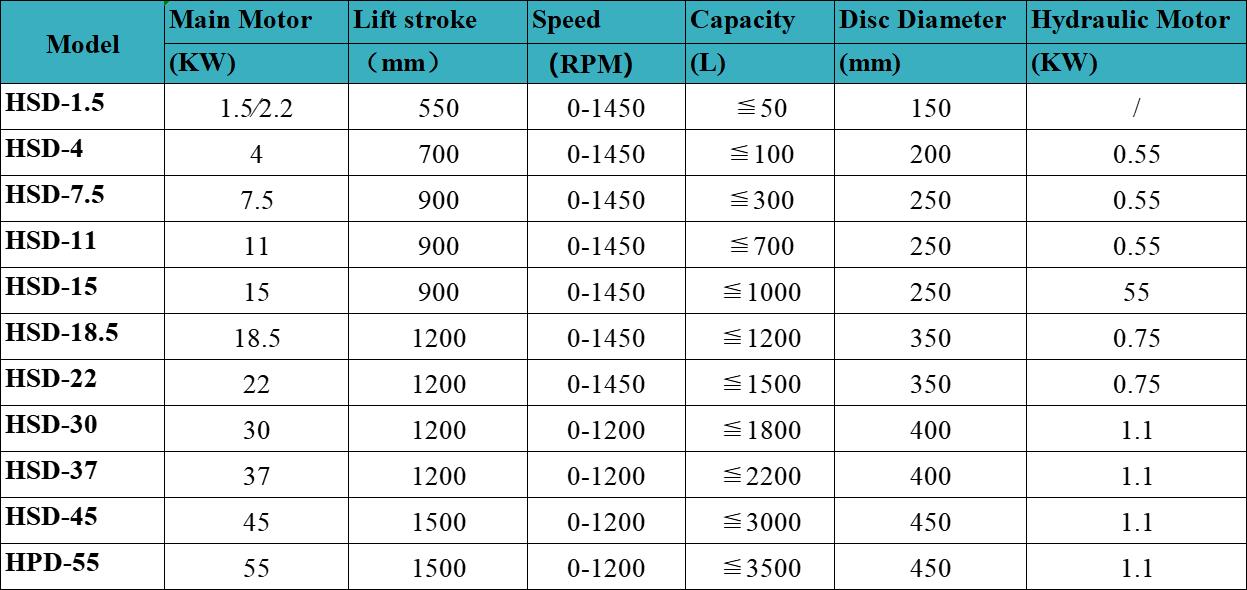

Main motor power range from 1.1KW to 110KW

Container is movable

Batch production range from 50 to 5000 liters

Zigzag round disperse disc

Options:

Fixed or pneumatic lid

360°rotary function for one disperser with 2-4 containers

Top-mounted type on the reactor with platform

Dual shaft

Scraper for containerwall

Vacuum defoaming

Double suction disc

PLC control

Technical Data:

Note: The data above is just for reference,material property and process affect the choice of specification a lot.

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China