Product:planetary mixer

Model:PMV series

Function:for mixing high viscosity materials

Application:sealant, adhesive, paste,gum,cream

SIEGMA-Fly your success!

Introduction:

PMV SERIES planetary mixer is an ideal equipment for stirring, mixing, dispersing and kneading of high viscosity and high solid content materials and Its unique stirring form can be efficiently stirred without dead angle. Usually there are 2-4 high and low speed agitators and 1-2 automatic scrapers in the kettle.The agitator rotates around the axis of the kettle body and rotates around its axis at different speeds at high speed, so that the materials move in the kettle body in a complex and fine way.In addition, the device is equipped with a separate scraper to continuously scrape the barrel wall.

The planetary mixer is driven by planetary gear, which has a large output torque. The machine is designed in closed form, which can be combined with the vacuum system to do vacuum mixing. The mixing barrel can be designed with jacket heating function. All these characteristics make it especially suitable for high solid, high viscosity, high temperature and other difficult working conditions.Actually,PMV series planetary mixer can process materials that viscosity reach to 1,000,000cps, and the solid content reach to 90%.

Working Principle:

The agitator form of PMV series planetary agitator can be selected according to the material viscosity and process characteristics, but usually consists of two low speed planetary agitator(multi - oblique paddle type, twist type, frame type),one or two high speed planetary stirrers (zigzag dispersing disc) and scraping paddles.These stirrers rotate around the axis at the same time of rotation, can evenly disperse the powder and additives into the slurry, with a strong dispersion effect.The low speed stirrer make the material turn, shear and mix in the container, and the toothed dispersing disc running at high speed forms turbulent flow to produce strong collision and shear between the mixed materials.At the same time, with the rotation of the stirring shaft, the scraper is also rotate so that the material on the kettle body is completely scraped off for avoiding stirring dead angle.Finally, under the combined force of high and low speed stirrers, the material can achieve effect of uniform mixing and dispersion.

Application:

For mixing and dispersing high viscosity, high solid content material.

Chemicals: a variety of sealant, adhesive, silicone sealant, polysulfide sealant, polyurethane sealant, structure of insulating glass sealant, waterproof sealant, sealant, anaerobic adhesive, stone glue, plastic mould, etc.), synthetic resin, rubber, printing ink, putty, abrasives (cream), wax products, synthetic rubber, synthetic resin, all kinds of powder materials, ceramic pigment; Electronic adhesive such as thermal adhesive, conductive adhesive, flame retardant adhesive, etc.;

New energy: all kinds of battery slurry, paste (lithium battery, nickel chromium battery, nickel metal hydride battery, fuel cell, power battery, etc.;

Electronic&electrical appliances: solder paste, ceramic paste, magnetic materials, silicone ink, electronic adhesive, PVC plastic, electronic and electrical parts potting glue, hot melt glue, all kinds of precious metal powder, slurry;

Cosmetics&daily chemicals: Moisturizer, lipstick, lip balm, lotion, gel, facial mask, mascara, foundation, nail polish, toothpaste, soap.

Food: all kinds of paste, paste type of mixture, seasoning, jam, chocolate paste.

Medicines: all kinds of soft ointment, polymer gel (medical paste, children's antipyretic paste, cold quick paste, ice paste, eye paste), dental products;

Main Features:

Suitable for stirring high viscous high solid content materials, stirring no dead Angle, viscosity can reach 1000000CPS above, applicable solid content up to 90%.

Laboratory and industrial processing capacity can be customized;common capacity ranged from 2L-1000L

Mechanical seal, dynamic seal and O-ring static seal, making the vacuum up to -0.098mpa,

It can choose electric heating, steam heating and other heating methods, temp controllable, accuracy ±1℃, range: 0-220℃;

Kneading and stirring at low speed and dispersing at high speed are integrated, which can run simultaneously or separately.

A variety of mixing configuration: twist frame, claw type, door frame type, blade type, etc.;

Discharging mode: extrusion discharging, positive pressure discharging, pump conveying;

Optional: Contact material (304/316L), contact material spraying, electrical control (explosion-proof type, control panel /PLC)

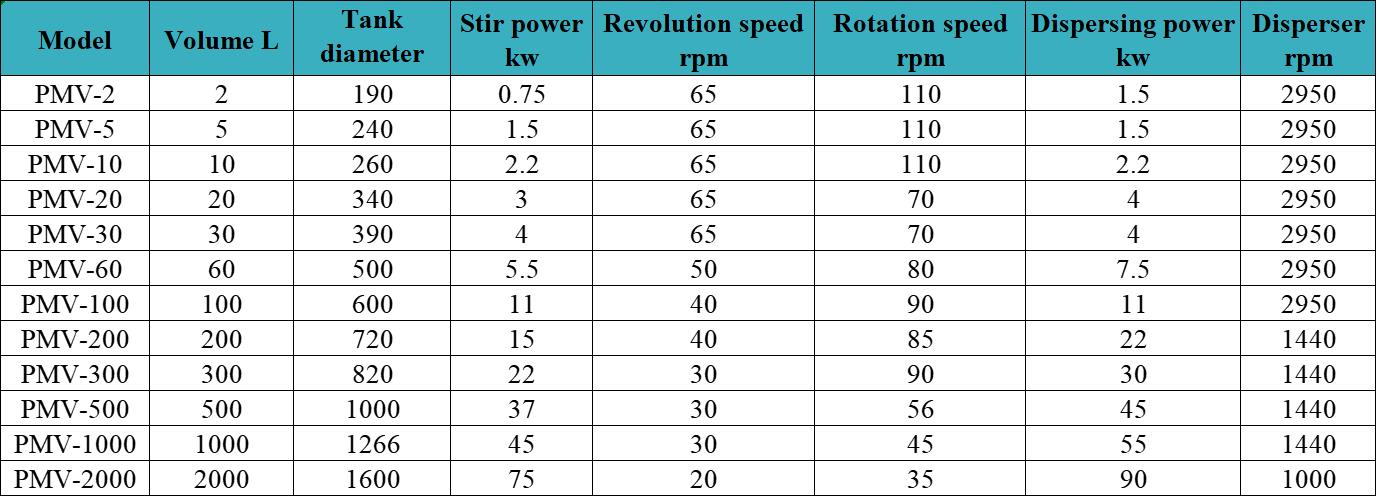

Technical Specification:

Note:Data is just for reference,viscosity and other materials properties can affect choice of specification.

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China