Product name:inline emulsifying pump

Function: dispersing,emulsifying,homogenizing

Application:chemicals,pharmaceuticals,food.

Color:blue,gree,grey,stainless steel

SIEGMA-Fly your success!

Introduction:

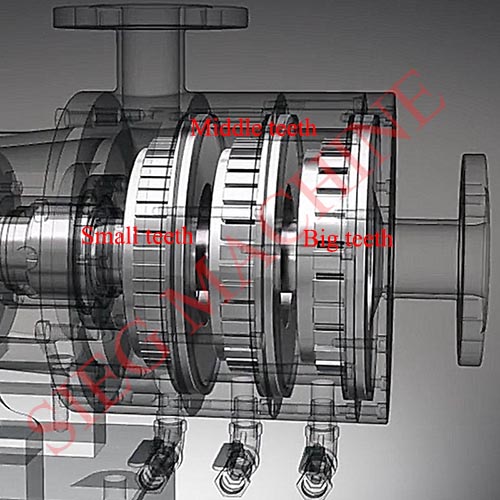

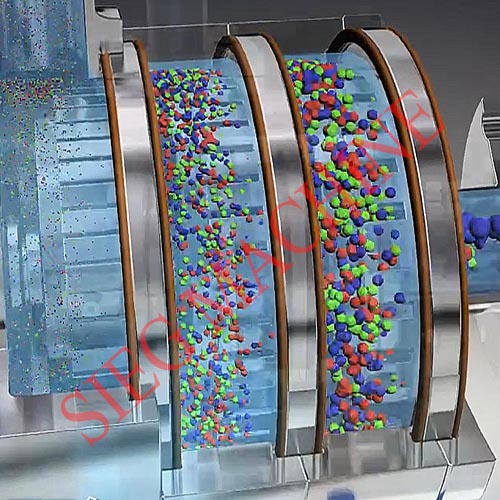

In-line emulsifier is used for emulsifying, homogenizing and dispersing products in industrial production. The grinding area is composed of stators and rotors with one stage, two stage and three stage.Besides, Each stage is respectively composed of three sets of grinding regions with coarse teeth, middle teeth and fine teeth so that materials can be crushed,dissolved,dispersed,homogenized and emulsified through this three grinding regions.

Working Principle:

The emulsifier uses a specially designed combination of high speed rotors and stators. Driven by the high-energy motor, the rotor produces extremely high linear velocity and strong mechanical kinetic energy, so that the material is subjected to shear, centrifugal extrusion, liquid layer friction, impact tear and turbulence in the precision gap of the rotors and stators, so as to achieve the effect of dispersion,homogenization, grinding and emulsification.

Main Features:

The working capacity is composed of three groups of rotors&stators (coarse teeth, medium teeth and fine teeth respectively), with high processing accuracy, large processing capacity and wide processing viscosity range, which is suitable for industrial inline production;

According to your materials, 304 or 316L is optional

Double end mechanical seal

Cooling system is optional

Adopt elastic connection mode, low noise and smooth operation.

Single stage emulsifying pump is available

Application:

Food industry: chili sauce, sesame, fruit tea, ice cream, cream, jam, fruit juice, soy, soy sauce, soy paste, peanut milk, protein milk, soy milk, dairy products, malted milk, essence, flavoring, all kinds of food and beverage, etc.

Chemical industry: paint, pigments, dyes, coatings, smooth oil, synthetic fat, smooth fat, diesel oil, petroleum catalyst, emulsified asphalt, modified asphalt, paraffin, adhesives, washing agents, plastics, explosives, FRP, synthetic leather, resin, plastics, leather and emulsified explosives, etc.

Daily chemicals: toothpaste, lotion, face cream, lip balm, facial cleanser, shampoo, shoe polish, high-end cosmetics, bath essence, soap, mixers, spices and balsam, etc.

Pharmaceutical industry: various types of syrup, nutrient solution, Chinese patent medicine, ointment, biological agents, cod liver oil, pollen, royal jelly, vaccines, all kinds of ointment, all kinds of oral liquid, fungicides, injections, antimicrobials, microcapsules and static drops, etc.

Construction industry: Various coatings. Including interior and exterior coatings, anticorrosive and waterproof coatings, cold porcelain coatings, colorful coatings, ceramic glazes, nano coatings and spraying, etc.

Paper industry: pulp, adhesive, rosin emulsion, paper auxiliaries, resin emulsion, etc.

Pesticide industry: fungicide, seed coating agent, herbicide, pesticide emulsion, chemical fertilizer, biochemical pesticides, biological pesticides and other industries:

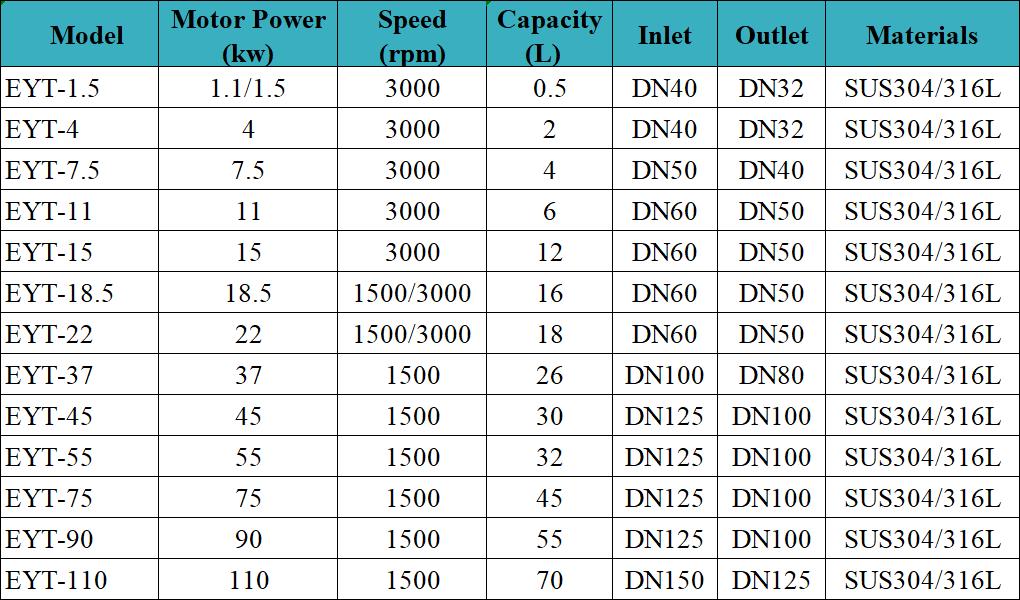

Technical Specification:

Note: data is just for reference,pls must comtact us for selecting proper specification.

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China