Product name:three roller mill

Model:TRL series

Fucnction:fine grinding for viscous materials

Apllication:inks,coating,metal paste,cosmetics

(SIEGMA-Focus on mixing&grinding technology)

Introduction:

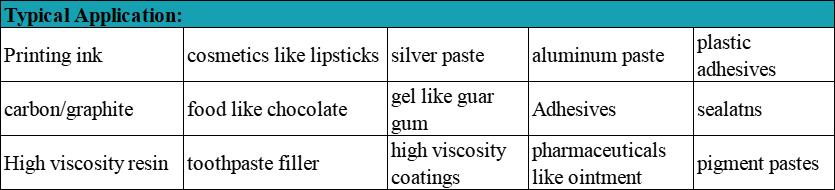

TRL series three-roller mill equipped with three horizontal and parallel rollers, which produce strong shear force due to the different running speed and direction of the three rollers, so as to realize the grinding, dispersion and mixing of viscous materials.They are widely used in grinding paste materials such as printing inks, high performance ceramic pastes, cosmetics such as lipsticks, plastic adhesives, carbon/graphite, high viscosity coatings,resins, ointments, dental fillers, adhesives, sealants and food such as chocolate paste,guar gum, Silver paste, aluminum paste, glass paste,etc.

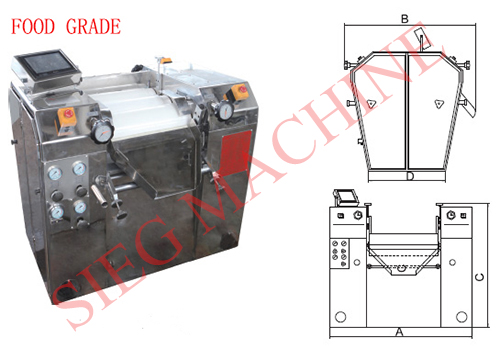

Three roller mill mainly consists of machine base, shell, roller, gear, bearing, baffle plate, receiving plate, scraper, handwheel, cooling system and other components. The middle roller position is fixed, the fast roller and the slow roller can be adjusted to control the fineness capacity through the parallel movement of the handwheel.

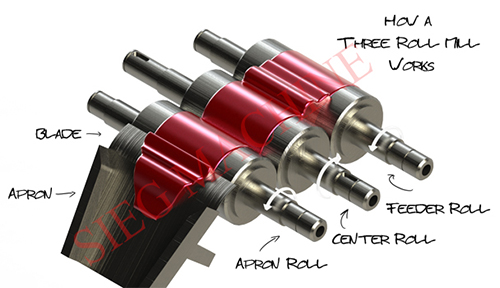

Working Principle:

As shown in the figure below, when the material is added from the area between the slow roller and the middle roller, only some of the material will pass the area between the slow roller and the middle roller at a time due to the gap between the two rollers is very narrow, and the rest will temporarily stay on the slow roller.

The material enter the area between the slow roller and the middle roller will be subjected to high shear force, so the particles will be evenly dispersed into the various types of binders.The material on the middle roller then enters the grinding area between the middle roller and the fast roller, because the front roller has a higher speed so that produces a greater shear force.Finally, a blade removes the dispersed and ground material from the fast roller and transfers it to the baffle.Usually, this process will be repeated several times until the particle fineness meets the product requirements.

Main Features:

Roller material is made of casting cold and hard alloy, its surface is extremely hard, high strength and high wear resistance.

Rollers processed by high precision fine grinding, high accuracy make the grinding fineness can reach to 5micron for most of materials.

Adjusting the horizontal handwheel screw can adjust the gap between rollers to adjust the fineness capacity. simple and accurate, easy to operate.

Automatic feeding is optional

Zirconia roller is optional

PLC control is optional

Food grade is optional.

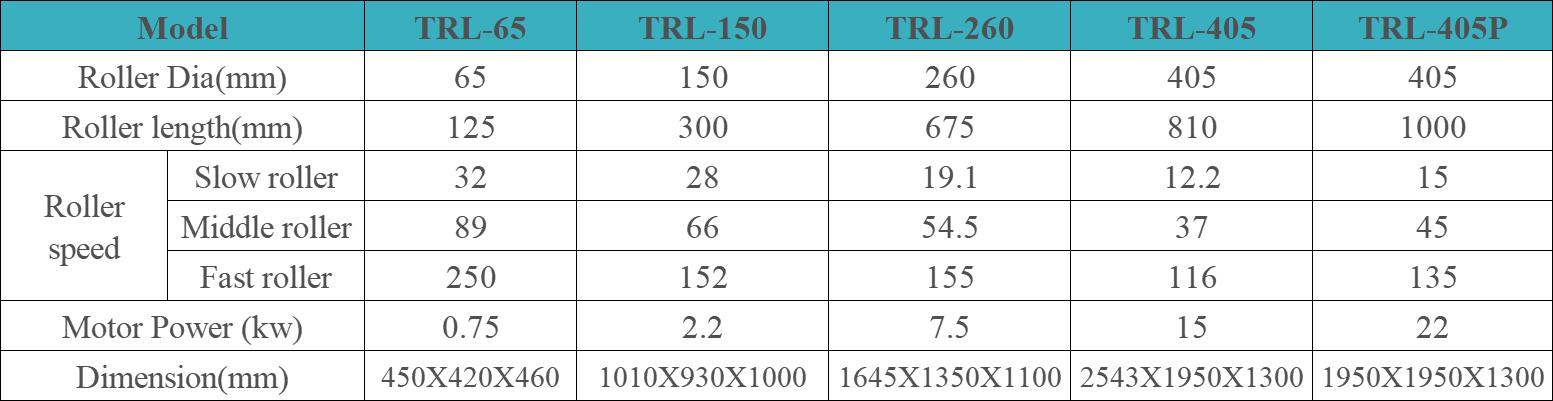

Technical Specification:

Note:data is just for reference,pls must contact us for selecting proper specification.

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China