Proudction name:ribbon mixer

Function:mixing powders,paste materials

Application:putty,coatings,medicines,chemicals

Color:blue,gree,grey and stainless steel

SIEGMA-Fly your success!

Introduction:

The ribbon mixer is generally used for mixing viscous or agglomerative powders and mixing of liquids or paste materials added to the powder. At the same time, considering the characteristics of difficult cleaning of viscous materials, it is better for mixing single product without frequent cleaning requirements. Ribbon mixer is extensively used in putty, stone paint, dry powder, medicine, food, chemicals, feed, ceramics, refractory materials and other solid-solid, solid-slurry mixing. In summary,ribbon mixer is suitable for powders and thick material mixing,but it is not suitable for the material with large fiber content and large density difference.

Working Principle:

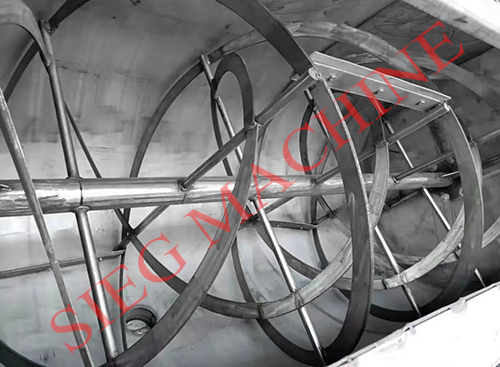

The model consists of a container, a spiral stirring blade and transmission system.Spiral blades are generally made of double or triple layers. The outer spiral will collect the material from both sides to the center, the inner spiral will transport the material from the center to both sides, so as to forming convective mixing. In summary:

Double spiral blades are arranged on the driving spindle of the mixer. The internal spiral transports the material to the outside, and the external spiral gathers the material to the inside.

Under the convection movement of the double spiral belt, the material forms an efficient mixing environment. The inner and outer diameter helix installed on the stirring shaft drives the material in the barrel body, so that the agitator turns the material in a large range in the container body.

Specification Guidance:

Determine the volume of each batch of mixed material, the range is 0.1-20 cubic meters, select the corresponding specifications of equipment.

The material of the equipment is selected, and the material is divided into: the part in contact with the material, the part not in contact with the material, and the other parts of the equipment keep the original material.

Material selection depends on material properties, working conditions, sanitary level and other factors. Conventional material is carbon steel, 304/316L/ stainless steel. After material selected, it can further determine the surface treatment technology.

Add auxiliary function components, such as liquid spraying, heating/cooling, etc., according to the actual process situation.

Determine the designing of opening , such as feeding port, cleaning port, vent, etc

Choosing discharging mode and driving mode, such as manual, pneumatic,hydraulic and electric

(Note:Customer should provide material details and the process arrangement, so that our engineer can provide you with technical services better.)

Technical Specification:

Note:data is just for reference,pls must contact us for choosing proper specification

Contact: Lucas Shu

Phone: +86-182 1718 6723

E-mail: export@siegmachine.com

Whatsapp:+86-182 6708 5695

Add: NO.556,caofeng road,Jiading district,Shanghai, China